Common Lab Mistakes That Affect Peptide Purity — And How to Avoid Them

Peptide purity is the backbone of reliable research. Even small deviations in integrity can skew results, inflate costs, and slow projects. In

Research-Use-Only (RUO) settings, disciplined handling, storage, and documentation are essential to protect data quality. This guide highlights the

most common lab mistakes that affect peptide purity — and how to avoid them with simple, validated best practices your team can implement today.

At-a-glance:

- Choose solvents and pH carefully during reconstitution.

- Prevent cross-contamination with strict aseptic technique.

- Control temperature, light, moisture, and oxygen exposure.

- Avoid repeated freeze–thaw cycles—aliquot early and smart.

- Maintain crystal-clear labeling and documentation.

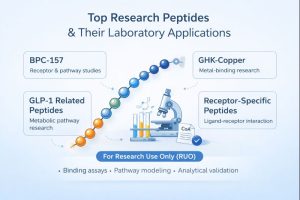

Understanding Peptide Purity and How It’s Verified

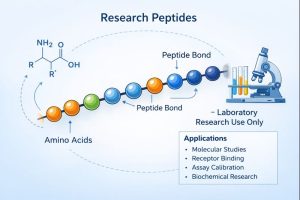

Peptide purity represents the proportion of the intended sequence relative to co-produced impurities (truncations, deletions, protecting-group remnants, oxidation products).

Suppliers typically assess purity via chromatographic and spectrometric methods. In practice, labs often work with 95%, 98%, or 99%+ analytical purity depending on assay sensitivity.

Peer-reviewed literature and vendor

application notes describe how High-Performance Liquid Chromatography (HPLC) separates components, while

Mass Spectrometry (MS) confirms molecular weight and identity. When received, compare your vial’s batch data to the

supplier’s Certificate of Analysis (COA) and file it with your

experiment records for traceability.

Mass Spectrometry – NIST.

The Top Laboratory Mistakes That Compromise Peptide Purity

1) Improper Reconstitution

Using the wrong solvent or pH can cause partial dissolution, hydrolysis, or aggregation. Always confirm solvent and pH guidance on the COA.

Hydrophobic sequences often need an organic co-solvent (e.g., acetonitrile, ethanol) or a small amount of DMSO prior to dilution into aqueous buffer. Gentle mixing is key—aggressive

vortexing or prolonged sonication may introduce heat and shear that promote degradation or aggregation.

- Start with a minimal volume of recommended solvent; then dilute into buffer.

- Allow time for passive dissolution; swirl gently instead of hard vortexing.

- Filter sterilize through low-protein-binding membranes after full dissolution if your workflow requires sterility.

2) Cross-Contamination During Handling

Trace carryover from pipette tips, benches, or reusable containers can contaminate peptide stocks. Use dedicated, sterile, disposable consumables. Work

within a clean environment (e.g., laminar flow hood) when handling multiple peptides side-by-side. Change gloves frequently and avoid open vials clustering in a single workspace.

- Use fresh tips and microtubes for each step and each peptide.

- Wipe-down routines: 70% IPA for surfaces; schedule regular deep cleans.

- Stage one peptide at a time to reduce mix-ups.

3) Incorrect Storage Conditions

The quartet of degradation—temperature, moisture, light, and oxygen—chips away at purity.

Store lyophilized peptides at −20 °C (or lower per COA) in sealed, desiccated vials. For light-sensitive sequences, use amber containers. Once reconstituted,

peptide stability drops; minimize time at room temp and follow COA guidance for refrigerated or frozen storage durations.

- Use desiccants and secondary containment to limit humidity.

- Keep freezer doors closed; avoid frost buildup and temperature swings.

- Consider inert gas (nitrogen/argon) headspace for oxidation-prone peptides.

4) Repeated Freeze–Thaw Cycles

Every thaw invites chemical and physical change. Aliquot immediately after reconstitution into single-use volumes. Label each aliquot clearly with peptide

ID, concentration, solvent/buffer, date, and preparer’s initials. This one habit alone prevents many purity issues and protects reproducibility.

5) Mislabeling and Documentation Errors

Misapplied labels, missing batch numbers, and ambiguous dates cause irretrievable confusion. Adopt a versioned template for vial labels and log sheets,

and use barcode or QR tracking when possible. Keep COAs, shipping receipts, and storage maps together in a shared repository to maintain chain-of-custody.

How to Maintain Peptide Purity: Proven Best Practices

| Area | Best Practice | Why It Matters |

|---|---|---|

| Reconstitution | Follow COA solvent & pH; dissolve gently; avoid overheating | Prevents aggregation, hydrolysis, and loss of activity |

| Aliquoting | Split into single-use vials immediately | Eliminates repeated freeze–thaw cycles |

| Storage | Low temp, desiccation, amber vials, inert gas where needed | Reduces moisture uptake, oxidation, and light degradation |

| Handling | Aseptic workflow, fresh tips/tubes, staged setup | Minimizes cross-contamination and mix-ups |

| Documentation | Consistent labels, batch/expiry tracking, centralized COAs | Protects traceability and audit readiness |

| QC Verification | Spot-check with HPLC or LC–MS before critical studies | Confirms purity/identity after storage or shipping |

Build a Simple SOP (Shareable, 1 Page)

- Verify COA specs; record batch number upon receipt.

- Reconstitute with recommended solvent/pH; gentle mixing only.

- Aliquot to single-use vials; label with ID, conc., date, initials.

- Store per COA; minimize light/moisture/oxygen; map freezer locations.

- Log every withdrawal; discard aliquots after use (no refreezing).

- QC spot-checks via HPLC/LC–MS before mission-critical experiments.

Quality Assurance: Checking Purity with HPLC and MS

Routine verification protects your downstream data. HPLC provides a purity profile (percentage of main peak vs. side products) and LC–MS confirms molecular mass.

For a helpful primer on liquid chromatography concepts, see this educational overview from ChemGuide (HPLC basics). For instrument-level details,

consult your platform’s application notes and methods guides.

Cross-check your results against the supplier COA and your storage log. If purity drifts or unexpected peaks emerge, investigate storage conditions,

solvent history, and handling steps before repeating critical assays.

Continue learning:

- Research Insights & Updates (PeptideVerse Blog)

- Understanding COAs for RUO Peptides

- Browse High-Purity RUO Peptides

All products are sold for Research Use Only (RUO). No medical, diagnostic, or therapeutic claims.

FAQs: Common Questions About Peptide Purity in Labs

1) How pure should a peptide be for RUO applications?

For most studies, ≥95% is a practical standard. Highly sensitive or quantitative assays may require ≥98–99%+ analytical purity.

2) Can I mix different peptides in a single solution?

Not recommended. Reconstitute separately to avoid cross-reactivity and precipitation that can reduce effective concentration and data clarity.

3) How long can reconstituted peptides be stored?

General guidance is 2–4 weeks at 4 °C, but always follow your COA. For longer durations, aliquot and freeze to minimize degradation.

4) What causes peptide degradation over time?

Temperature cycling, moisture uptake, photo-exposure, and oxidation are the main drivers. Manage these with robust storage controls.

5) How can I tell if a peptide has degraded?

Look for cloudiness, color shifts, or unexpected HPLC/LC–MS peaks. If you see drift, verify purity before proceeding with key experiments.

6) Should I test peptide purity after long-term storage?

Yes. Spot-checks preserve confidence in your results and help you catch issues early.

Conclusion: Protect Research Integrity by Protecting Purity

The easiest path to reproducible results is avoiding the common pitfalls: solvent mismatch, cross-contamination, weak labeling,

inadequate storage, and repeated freeze–thaw cycles. By implementing a tight SOP, aliquoting early, and verifying with HPLC/LC–MS,

your team will protect peptide integrity and streamline experimental success.

External resources for further reading:

NIST – Mass Spectrometry •

ChemGuide – HPLC Basics •

Nature – Peptide Chemistry Topic Hub